Test Rig for Packings

The test rig TEMES stb.freak allows to determine

- deformation properties,

- friction characteristics and

- tightness characteristics

of stuffing box packings.

The core of this test rig is the simulation of a valve stem / packing interaction.

There are standard geometries available, additionally individual housing and stem combinations can be manufactured.

Layout and function

The test rig TEMESstb.freak consists of

- a mechanical test device (body and valve stem),

- a control cabinet,

- a cooling unit,

- a leakage unit,

- a computer and

- a monitor.

Optionally,

- a mass spectrometer or

- a flame ionization detector

can be added to the test rig.

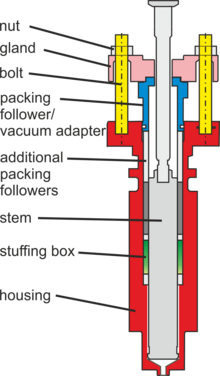

In the test rig, standard packings size is 56 x 40 mm (2.2"x1.6"), up to 8 packing rings can be installed. The maximal load that can be transferred on the specimen is a force of about 100 kN; that is equivalent with a contact pressure of 65 MPa (9430psi).

An adjustable heating device allows packing tests at temperatures up to 400 °C (750 F) with a maximal internal pressure of 200 bar (2900psi).

Stem diameters can be realized up to 60 mm (2.36").

In addition to the gland bolt force and the spindle force, the deformation of the packing and the spindle stroke are measured, continuously. Temperature measuring points are located at various points on the test stand, e.g. in different areas of the housing and on the supply line of the test medium.

In the case of leakage measurements, the internal pressure is measured using an absolute pressure sensor, and the test pressure can also be set in this way. The leakage rate can be measured using either the pressure drop method with a differential pressure sensor or the vacuum method with a helium mass spectrometer. If Methane is used as test medium, a flame ionization detector can be used to measure the concentration of hydrocarbons.

All operating functions of the test rig can be controlled absolute manually, however, with the software package TEMES stb.freak which is included in the delivery, also a fully automated test run and measured value acquisition of numerous tests is possible.